URC(fabric formwork)Architecture

Using fabric for concrete formwork, I named URC. U stands for the initial of my name:“Unno Rainforced Concrete”.

The first house I designed was「A high heat accumulation House 1」in 1997年.

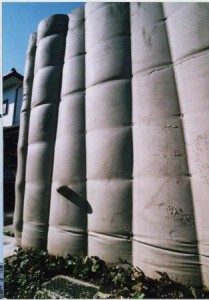

The great characteristic of this method is to use fabric for concrete framework.

URC provides soft expression of its finish and is quite different from RC structure in existence.

In addition, the fabric formwork creates precise condition of concrete constructions by ejecting redundant water and also eliminates air bubble on the surface of concrete which increase in intensity of concrete, as a result, slowing down deterioration of concrete constructions.

One other thing to note here is to reduce the amount of materials consumed in concrete formwork constructions.

The fabric formwork expands a wide variety of designs, but that is not my intention.

My main purpose of URC method is to continue to design and construction research just simplifying every aspect of fabric-formed concrete and constructions.

So people can use to build house for themselves.

Concrete provides a high thermal content.

Adopting exterior thermal insulation in building can create a large amount of thermal content in a room.

This could changes the element of current living environment.

That is a thermal storage system.

Exterior thermal insulation and well-insulated have been mainstream on buildings but thermal storage system will be added to it from now on.

URC method is predicated on the exterior thermal insulation.

RC structure house is totally failure as far as exterior thermal insulation is concerned.

I have been built many residential houses in my carrier but not RC structure even though I like the style very much. However, adopting the exterior thermal insulation on RC structure will be truly different story.

It will give us very comfortable indoor thermal environment.

The Great Hanshin-Awaji (Kobe) Earthquake in January, 1997 motivated me to start developing URC method.

I asked myself over and over again what I would do if I were victim of earthquake,.In conclusion, I would build a sturdy house with high quality of thermal environment.

A strong solid material in construction will be concrete.

I had started thinking of a simple way to build concrete house with exterior thermal insulation.

A small office like mine had limitations, I could not meet budget for full-scale of experimental trial.

In 1997, two years after the earthquake, I finally had an opportunity to build case study house.

And then, I made additional improvements every time I received orders.

In 2003, I won a prize from the Good Design Award and a special award for excellence from The Second Jyukukan Design Conpetition on「Gyousouan」

I wonder there is anyone who uses fabric for concrete formwork in the world.

One day, Professor Mark West, University of Manitoba, Canada, came to visit.

He has been studying and fabricating architectural joist and post utilizing fabric formwork.

He had a strong interest in that I have been actually building a house with this method.

There are about 10 researchers who have been working on fabric formwork around the world.

Mark invited me to join the conference he convened in University of Manitoba.

I was only one, at that time, who actually building architectural space by fabric for concrete formwork.

blog「世界のfabric formwork建築」